In the busy corridors of manufacturing plants, the pristine environments of healthcare facilities, and the dynamic operations of transportation and logistics firms, one...

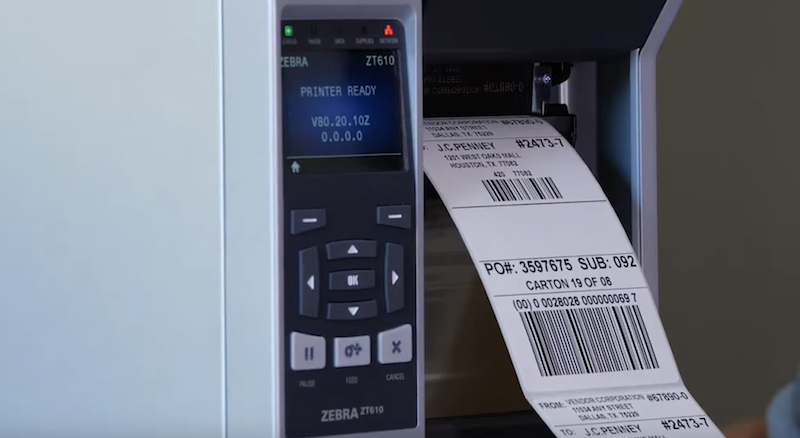

Streamline your supply chain with a centralized database and decentralized printing.

Having labeling issues?

If any of these sound familiar, you might consider working with a professional to streamline and modernize your processes --- specifically, by implementing a point-of-use labeling system.

Small Business Lean Labeling Examples

Deli Chain Avoids Costly Ingredient Change

A large Manhattan-based deli chain has concession stands in train stations and subway stops throughout New York City. They decided to sell identical and uniform sandwiches across all locations, and purchased pre-printed labels to handle the large task. The only problem was, they soon after decided to change the recipe on one of the sandwiches --- simply by altering one ingredient. This small change resulted in a sunk cost of about $40,000 in now obsolete and useless labels.

Now that the deli has upgraded to a point-of-use labeling solution powered by BarTender, they only label on an as-sold basis, using one centralized template that can easily handle any ingredient modifications.

Boat Products Supplier Prevents Closet From Filling Up With Clutter

A boat paint supplier was making custom labels for his different paint colors. But each time he adjusted the ingredients in the paint, or altered the color even slightly, he ended up with a closet full of useless labels. Now with point-of-use setup, our boat paint supplier is free to tinker with colors all he wants!

Point of use labeling saved both of these businesses tens of thousands of dollars in the first year alone.

Benefits of Lean Labeling in Your Operations

How soon can we be up and running?

You can be up and running with a point-of-use labeling solution powered by BarTender in as little as three days.

Wrapping Up

Are you having brand consistency problems? Quality control issues related to labeling? Is your labeling process slowing down your shipping and receiving?

When you’re not properly centralized, all of this can (and often does) happen.

We like to think of it in terms of “Operations 360,” which means constantly looking at improving:

READY TO GET STARTED RIGHT AWAY? USE THE FORM BELOW & TELL US ABOUT YOUR BARCODING & LABELING NEEDS. WE'LL GET BACK TO YOU WITHIN ONE BUSINESS DAY.

In the busy corridors of manufacturing plants, the pristine environments of healthcare facilities, and the dynamic operations of transportation and logistics firms, one...